rockwell hardness test indenters|rockwell hardness test methodology : wholesalers Hardness testing plays a vital role in materials testing, quality control, and component acceptance. Buehler provides a complete range of indenters designed for Vickers, Knoop, Rockwell, and Brinell scales.

Resultado da 13 de dez. de 2023 · O influenciador fitness Renato Cariani é investigado pela Polícia Federal, . Atirador de elite dispara na mão de homem que fazia filha refém. Criança foi resgatada sem ferimentos. Homem foi .

{plog:ftitle_list}

web22 de out. de 2022 · Ad. Récapitulatif. Montpellier Hérault Olympique Lyonnais. Découvrir le récapitulatif complet. Statistiques. Montpellier Hérault. Olympique Lyonnais. 1. Buts. .

rockwell hardness testing equipment

Gilmore Diamond Tools’ manufactures diamond indenters and penetrators for all makes and models of Rockwell hardness testing machines – as well as custom indenters for use in difficult testing situations.Gilmore Diamond manufactures many accessories specifically designed for .Indenters Hardness Test Blocks. Brinell Scale. Nano / Instrumented Indentation .

Diamond Indenters are in stock for all makes and models of Rockwell .

Indenters. According to the latest standards, there are changes to both Rockwell and Brinell scales. The test method for Rockwell testing (ASTM E-18-08a) only allows the use of .

Hardness testing plays a vital role in materials testing, quality control, and component acceptance. Buehler provides a complete range of indenters designed for Vickers, Knoop, Rockwell, and Brinell scales.In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured. In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods. A Rockwell hardness tester. The Rockwell scale is a hardness .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

The Rockwell hardness test utilizes 1 of 6 different main loads: In total, this gives 30 different Rockwell scales. Each one is characterized by a different combination of indenter type and main load, and is suitable for a particular material or .Diamond Indenters are in stock for all makes and models of Rockwell Hardness Testing Machines. “Special Indenters” are manufactured to blueprint specifications. All Indenters are .

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter is measured. In contrast, the indentation size is measured in the Brinell, Vickers and Knoop optical test methods.See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters 1 Scope This document specifies two separate methods of verification of testing machines (direct and indirect) for determining Rockwell hardness in accordance with ISO 6508-1, together with a method for verifyingAMETEK makes a variety of Newage indenters and indenter accessories. According to the latest standards, there are changes to both Rockwell and Brinell scales. The test method for Rockwell testing (ASTM E-18-08a) only allows .

Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .All rockwell diamond indenters are performance-tested on a master Rockwell hardness tester in our environmentally controlled ISO 17025 standardizing laboratory. The indenters are then compared to a 0-0 master indenter within a tight tolerance established by the WESTport Hardness Testing Standards Laboratory.

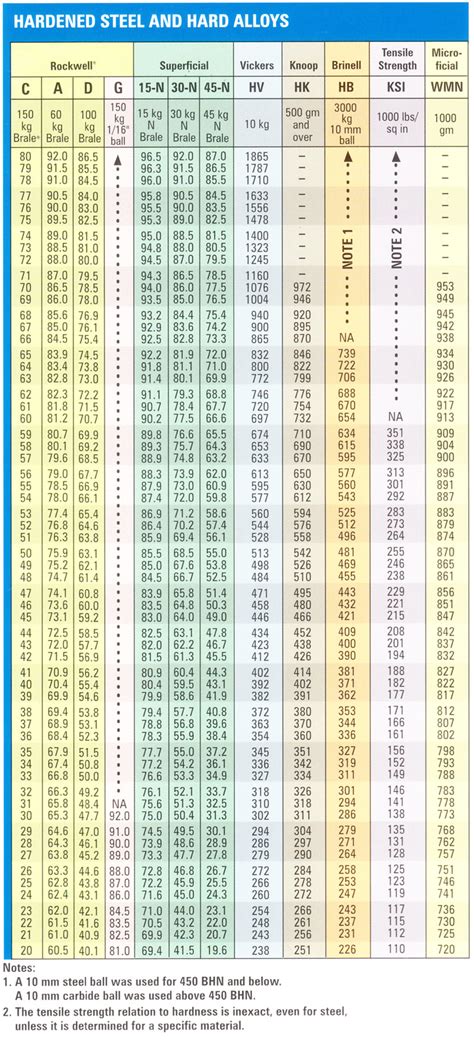

rockwell hardness tester chart

Find a full range of accessories for Vickers, Knoop, Brinell and Rockwell hardness testing, from specimen holders, clamps, vices and jaws to test blocks, indenters and lenses.This set of Testing of Materials Multiple Choice Questions & Answers (MCQs) focuses on “Rockwell Hardness Test”. 1. Which hardness test is most widely used in the US? a) Brinell b) Vickers c) Shore d) Rockwell View Answer. . Explanation: Indenters should be changed according to the hardness of the specimen. It takes less time to perform .Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness TestingThe aim of this round robin test was to discover what needs to be done to achieve the world- wide unification of Rockwell hardness scales using diamond indenters (HRC, HRA, HRD, HR15N, HR30N and HR45N) (1) - (5). These scales are the most commonly

Explore Suntec's wide range of hardness testing indenters. Choose from various options for accurate and consistent material hardness assessments. Trust our high-quality indenters for reliable results. . Rockwell Type Diamond Indenter Select options This product has multiple variants. The options may be chosen on the product page

Gilmore Diamond Tools manufactures hardness testing indenters and test blocks for Rockwell, Vickers, Knoop, and Brinell hardness scales. Gilmore also makes and sells diamond tools for measuring and manufacturing applications, such as Diamond Stylus, Diamond Dressing Tools and Diamond Scribes. We are the only U.S. diamond indenter manufacturer accredited by the . Rockwell hardness testing can determine the hardness of most metals, alloys and plastics. . 100 or 150 kg total test forces combined with diamond; 1⁄16, 1⁄8, 1⁄4 and 1⁄2-inch diameter ball indenters; and 0.2 millimeter per Rockwell point. These forces are called the Regular Rockwell scales. The HRC, for hardened steels, and the HRB .In tungsten carbide hardness testing Rockwell hardness of HRA is often used. HRA, named Rockwell Hardness A scale, which as the initial pressure uses 98.07N (equal to 10kgf), use a diamond pressure head with 120°cone apex angle or steel ball with 1.59, 3.18mm in diameter and then pressurized to 588.4N (equal to 60kgf).Indentron deadweight Rockwell hardness tester. Unique design eliminates frictional inconsistencies. Regular, superficial & combination units available. Skip to content. . to within 1/4-inch with the standard indenter and up to 3/32-inch with optional special indenters. Testing is fast, accurate and there are fewer broken diamonds due to an .

All rockwell diamond indenters are performance-tested on a master Rockwell hardness tester in our environmentally controlled ISO 17025 standardizing laboratory. The indenters are then compared to a 0-0 master indenter within . Ball sizes of the indenters: 1/16``, 1/8``, 1/4``, 1/2``

Rockwell hardness test, as a measure of the resistance of a material to localized plastic deformation, is a valuable and widely used mechanical test. However, the accuracy of Rockwell hardness measurement is still in question. The indenter, including both the spheroconical diamond indenter and ball indenter, is a major contributor to Rockwell .Hardness tests can be defined as forcing an hardness testing indenter of a specified size, shape, and material into the surface of a test piece to obtain a hardness value. Skip to content +1 847-295-6500; . Rockwell indenters fit on R574, RH2150, RB2000, and Wilson legacy testers. *C, D, and A scales refer to regular Rockwell scales, N scales .Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters . together with a method for verifying Rockwell hardness indenters. The direct verification method is used to determine whether the main parameters associated with the machine function, such as applied force, depth .

Abstract. The difficulty in manufacturing Rockwell diamond indenters to the required geometric specifications has resulted in most commercially manufactured indenters to vary in shape from one to another. This difference in shape is thought to be a major contributor to the Rockwell C scale hardness measurement uncertainty. In this paper, a finite-element analysis .

6 Calibration and verification of Rockwell hardness indenters . Before a Rockwell hardness testing machine is verified, the machine shall be checked to ensure that it is properly set up and operating in accordance with the manufacturer’s instructions. Especially, it should be checked that the test force can be applied and removed without .

Gilmore Diamond Tools manufactures hardness testing indenters,test blocks, and accessories for Rockwell, Vickers, Knoop, and Brinell hardness scales. Gilmore is the U.S. diamond indenter manufacturer accredited by the United States Department of Commerce / N.I.S.T. for the measurement and calibration of diamond indenters. Our calibration laboratory is an NVLAP . By using standard indenters in standard hardness machines under a standardized testing cycle, it should be possible to establish a worldwide unified Rockwell scale with metrological traceability and reproducibility, and without significant bias to the ideal scale. Recent geometric measurements and hardness testing results support this approach.Gilmore Rockwell Hardness Test Blocks (also known as Rockwell Test Coupons) are manufactured and calibrated to current ASTM E-18 and/or ISO 6508 specifications within an ISO 17025 accredited laboratory. We offer Rockwell test blocks for all Rockwell Hardness scales for use with a large variety of penetrators and loads. . Indenters Hardness .The aim of this round robin test was to discover what needs to be done to achieve the world- wide unification of Rockwell hardness scales using diamond indenters (HRC, HRA, HRD, HR15N, HR30N and HR45N) (1) - (5). These scales are the most commonly

Specification of Hardness Testing M/C and Indenters:. Rockwell hardness testing machine essentially consist of a supporting table for placing the specimen, a hand wheel to raise or lower the supporting table, a Rockwell ball indenter which is a hardened steel ball 1/6'' in diameter, a Rockwell cone indenter which is a diamond cone of 120°. Rockwell hardness (HR) is a valuable and widely used indentation hardness test for evaluating mechanical properites of metallic materials. . The effects of four different sizes of steel and WC ball indenters on different Rockwell hardness scales are studied and compared with experimental measurements. This study provides important .

Ian Neves e Humberto Matos de um lado da mesa e do outro Paulo Galo e Chavoso da Usp. Confira esse episódio que tá sensa. – Listen to 154 - Ian Neves & Humberto .

rockwell hardness test indenters|rockwell hardness test methodology